Warehouse automation has become an increasingly popular solution for companies looking to improve their supply chain efficiency and reduce costs. In this article, we will explore the benefits and challenges of implementing automation in warehouse operations, as well as the different types of technology available for tracking and moving goods.

AI That Generates Images From Text

What is Warehouse Automation?

Warehouse automation refers to the use of technology to mechanize traditional warehouse operations. This includes the use of robotics and AI as well as machine learning. By eliminating manual labor in many processes, automation enhances efficiency, reduces errors, and allows for more accurate inventory tracking.

The need for automation in warehouses has arisen due to the cost pressure and the need for efficiency in supply chains. Automation can help reduce labor costs, improve accuracy, and increase productivity. With the rise of e-commerce and the demand for faster delivery times, automation has become a necessity for many companies.

Types of Automation Technology

Warehouse automation is not a one-size-fits-all concept. It encompasses a range of technologies and systems, each designed to streamline specific warehouse operations. Here, let’s look at some of the main types of warehouse automation:

Automated Storage and Retrieval Systems (AS/RS): This type of automation handles storing and retrieving items in a warehouse. For instance, Amazon uses Kiva robots to transport goods around its warehouses, minimizing human intervention.

Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs): These self-guided robots carry materials around the warehouse, following a set path or navigating autonomously.

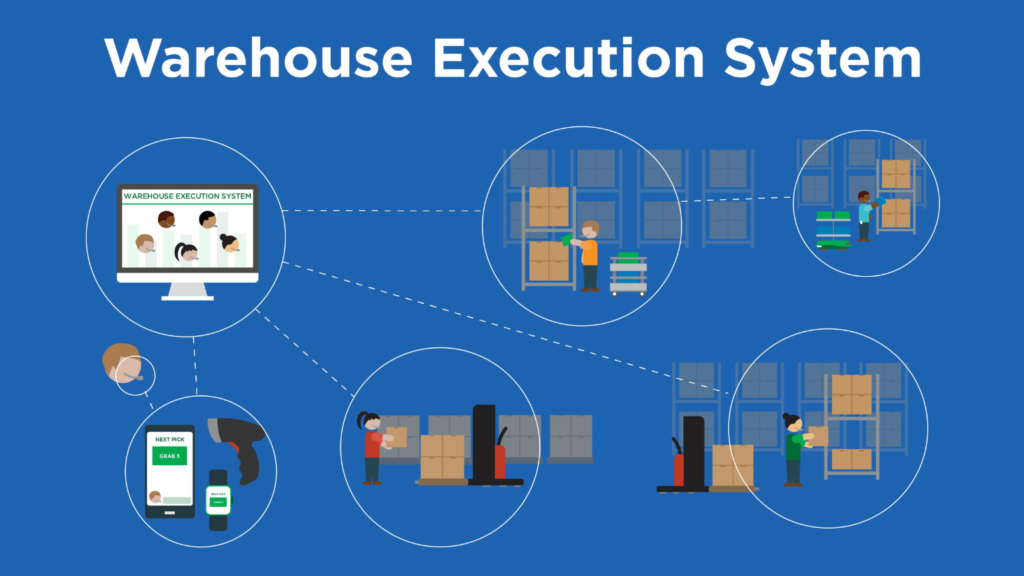

Warehouse Execution Systems (WES): WES are execution systems that coordinate and direct the various automated elements within the warehouse, maximizing efficiency.

Sortation Systems: These automated systems sort a wide variety of items at high speeds, facilitating quicker order fulfillment.

Conveyor and Conveyor Belt Systems: Traditional yet effective, these systems transport goods from one area of the warehouse to another, reducing manual handling and enhancing efficiency.

Picking Systems: Automated picking systems, such as pick-to-light or voice-directed picking, speed up the picking process and reduce errors.

Front End vs Back End Languages

Benefits of Automation

One of the main benefits of automation is increased efficiency. Automated systems can work around the clock, reducing the need for human labor and increasing productivity. Automation can also improve accuracy, reducing the risk of errors and improving inventory management. Additionally, automation can help reduce costs by reducing labor costs and improving inventory management.

Challenges of Automation

While automation can bring many benefits, there are also several challenges to consider. One of the main challenges is the cost of implementation. Automation systems can be expensive to install and maintain, and may require significant changes to the warehouse layout. Additionally, automation can lead to job loss, which can be a concern for employees.

Future of Automation

As technology continues to advance, the future of warehouse automation looks promising. New technologies such as drones and autonomous mobile robots (AMRs) are being developed to further improve warehouse efficiency. Additionally, the use of artificial intelligence (AI) and machine learning can help optimize warehouse operations and improve inventory management. For example, AI can be used to predict demand and optimize inventory levels, reducing the risk of stockouts and overstocking.

Conclusion

Warehouse automation has become a necessity for many companies looking to improve their supply chain efficiency and reduce costs. While there are challenges to consider, the benefits of automation are clear. Automation can help companies improve their productivity, accuracy, and inventory management, while reducing labor costs. As technology continues to advance, the future of warehouse automation looks promising, with new technologies and innovations being developed to further improve efficiency and reduce costs. Companies that invest in automation now will be better positioned to compete in the future and meet the demands of their customers.